Do you know one of the biggest challenges a semi-truck fleet manager faces? It is the sudden breakdown of a vehicle. However, this problem can be eliminated with an effective preventive maintenance plan.

So, what is preventive maintenance? Just like our body requires food & exercise every day to remain healthy, semi-trucks also need daily and routine care. It ensures that they run smoothly, thereby offering you the best productivity.

Once a semi-truck fleet preventive maintenance schedule is in place, you will no longer need to worry about delays and inconvenience and can focus on other necessary business operations.

To make your job easier, we have created this guide and a checklist that will help you identify the Preventative Maintenance for Semi-Trucks and create a schedule accordingly.

What are the Benefits of a Preventive Maintenance Schedule For Your Semi-truck Fleet?

Preventive maintenance has several benefits, and it can enhance fleet performance.

- Vehicle Efficiency: Routine maintenance often helps identify problem areas, thereby minimizing the likelihood of malfunctions on the road. You can ascertain that your semi-truck works without a hitch by fixing issues in its initial stages.

- Improve the health and life of your assets: Another benefit of preventive maintenance is improved vehicle health. With regular maintenance, you can minimize the wear and tear of the truck. You can also spot and address slight issues on time.

- Smooth and streamlined Operations: Regular maintenance ensures smooth operations and no or minimal breakdown.

- Cost Efficiency : (Minor issues cost less rather than fixing problems later) When you check your vehicle regularly, you can identify issues & resolve them on time before they become big.

- Safety standards and regulations: With regular maintenance, you can comply with the FMCSA’s regulations, and ensure that your fleet meets the set safety standards and regulations.

- Resale Value: What if you want to sell your semi-truck in the future to acquire some other asset? If you are continuously servicing your vehicle, it would maintain its resale value, and you will get a good deal for it.

- Overall Fleet Management: Lastly, regular maintenance ensures that every aspect of the fleet is working smoothly, straight from route management to delivering the loads on time to your customers.

Below are some causes that can cause damage to your semi-truck.

- Engine or brake failure

- Accidents of the vehicle

- Irregular servicing or not sending vehicles to the service center for a long time

- Poor driving habits of your drivers

- Drivers not trained to identify potential issues

- Not using telematics solutions to track your vehicle and access data

- Poor route management

- Driving through rough terrain or in harsh climatic conditions

As a business owner, you have to identify these potential threats and develop an effective strategy to mitigate these to ensure smooth operations.

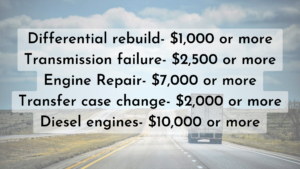

Here are the top costly repairs in the trucking industry:

Note: These prices are subject to change according to your region, truck, and garage. You can refer to this data for a quick estimation only.

Complete Preventive Maintenance Schedule For Your Semi-truck

Regular Inspection

You should start by maintaining a regular inspection plan. You should thoroughly check your semi-truck before and after every trip.

FMCSA requires drivers to fill DVIR (Driver Vehicle Inspection Report) form regularly to notify fleet managers about any issue with the vehicle to prevent mishaps in the future. You can take this compliance step to the next step by customizing the inspection form. While you can get many pre-made ones in the market, getting your customized ones will allow you to identify issues on time to prevent costly repairs in the future.

Tip:- Daily inspection can include a checklist of items before and after every trip. Add every safety component to the list, such as windshield seat belts, brakes, horns, lights, leakage inspection, etc.

You can also pay attention to the fuel consumption of a vehicle to spot any issues with the semi-trucks.

How? If one of your vehicles shows a sudden increase in fuel consumption, you can check for the engine or other parts. It can also be linked to the driver’s driving behavior.

Develop Maintenance Checklist

Develop a checklist to ensure you don’t miss any sphere of vehicle maintenance. Here are some items you need to have on your list to ensure smooth operations.

- Oil change

- Air-filter replacement

- Brake inspection

- Tire rotation and inspection

- Cooling system maintenance

- Battery maintenance

- Transition service

- Fuel system maintenance

- Suspension maintenance

- Electrical system inspection

- Steering and suspension check

- Exhaust system maintenance

- Lights inspection

- Windshield wipers service

- Ensure seat belts, horns, and other systems are in good condition

Vehicle Information

Remember that every vehicle in your fleet is unique and needs its maintenance plan. For example, you should pay attention to how much a vehicle is driven, its mileage, weather conditions, road conditions, fuel type, and the driver.

Hiring Drivers

Drivers play a huge role in vehicle maintenance. They are responsible for driving the trucks and can understand it better than you do. Their driving skills also determine how often you must take your semi-truck to the service center.

So where does all of this begin? Hiring a good driver, right?

So the next time you hire your employees, have a clear idea of your requirements. Generate a clear job description that mentions everything about the job duty and qualifications required. You can also conduct a background check to access their driving records to ensure that they have good driving behavior. You can also execute a test to assess the knowledge of the recruits.

Lubricating Vehicles Parts

You should also regularly lubricate the moving parts of the vehicles to prevent regular wear and tear.

Replacing Used Parts

While changing and replacing any part of the vehicle, choose the best part for replacing components. It will ensure the reliability of the semi-truck and reduce the risk of future breakdown.

Regularly Cleaning Vehicle

The vehicle reflects a company’s image and can make your business reputation. You need to ensure that the semi-truck appears clean and professional. So while making a maintenance schedule, give your drivers time to clean the truck after using it.

Sticking To Your Maintenance Plan

What is the use of making a good strategy, if you never follow it? And therefore, the most crucial thing is to create a good maintenance plan that includes implementation.

Divide the responsibility among your employees effectively. It will help you ensure that vehicles are always working and in their best condition. You can also organize training programs for your drivers to help them identify any potential issues that can become big in the future to cause a breakdown.

Use Inspection As Learning Opportunity

When you are taking your vehicle to the service center, make sure to use this as a learning opportunity. You could collect these statistics to develop an efficient schedule that can address individual truck demands in your fleet.

Investing In The Fleet Telematics Software

The fleet management system can also help you in fleet maintenance. The best part of this solution is that it helps to track the whole life cycle of the vehicle in your fleet, straight from its acquisition to its disposal.

It can give you accurate information about its condition and send you reminders so that you don’t have to remember the date of every truck in your fleet. In this, you can stay on top of maintenance and prevent any unfortunate events in the future.

Fleet management technology can simplify your job, and you will not have to worry about managing everything as you have a reliable partner beside you.

- GPS Tracker

GPS trackers provide real-time location information about the vehicle and keep you updated on its location 24/7. You can also track it when it is in the service center and prevent unauthorized use.

- Compliance

The ELD device is directly connected to the vehicle’s engine through the diagnostic force and pulls out crucial data, including engine conditions, tire pressure, and gallons per mile. You can use this data to make effective decisions for your truck.

- Monitor Fuel Consumption

Fleet management systems can also help you to monitor fuel consumption. You can analyze the fuel usage trends and spot any irregularities in the pattern.

In this way, you will be able to rectify any issue on time before they transform into more prominent & costly repairs.

- Prevent Reckless Driving Behaviour

Reckless driving is not good for any fleet. You have to identify and prevent it on time before it transforms into a misfortune event. A fleet management system allows you to monitor the real-time activity of your driver. It also sends you a notification as it detects any reckless driving activity. In this way, you can train your drivers and improve safety in your organization.

- Maintenance Reminders

It is hard to remember the maintenance schedule of every truck in your fleet. A fleet management system sends notifications to remind you of every single servicing date. In this way, you won’t have to memorize the dates and can focus on other areas.

- Route Management

You can also use fleet management statistics to optimize route management. You can see the real-time statistics of the road condition and choose the best possible path to minimize the depreciation of your semi-trucks.

- Collect Significant Data

Fleet management collects all the data and generates visual reports so that you can use them to make impactful decisions for your business.

Bonus Tip

If you want to incorporate technology in your fleet but are worried about your budget restraints and complexities associated, then you must check out Matrack. It provides one of the most cost-effective and easy-to-use fleet tracking technologies. It also comes with an integrated mobile application, web portal, and 24/7 support team that will readily help you to resolve all your issues.

Conclusion

Preventive maintenance is essential for your fleet management, and you cannot ignore it to ensure smooth operations.

You can use this guide to create an effective preventive maintenance strategy for your semi-truck fleet to ensure smooth operations and increase efficiency.

Also, after building an effective maintenance strategy, stick to your schedule. Don’t skip a single inspection schedule, even if you think everything is fine.

Frequently Asked Questions

Q: Why is preventative maintenance important for semi-trucks?

A: Preventative maintenance is important for semi-trucks because they are often subjected to heavy use and long distances, and breakdowns can be costly and dangerous. Regular maintenance helps identify potential issues before they become major problems and keeps the truck running efficiently.

Q: What are some common types of preventative maintenance for semi-trucks?

A: Common types of preventative maintenance for semi-trucks include oil changes, tire rotations, brake inspections, fluid checks, and electrical system inspections.

Q: How often should preventative maintenance be performed on a semi-truck?

A: The frequency of preventative maintenance for a semi-truck will depend on a number of factors, such as the age and condition of the truck, the type of operation it is used for, and the manufacturer’s recommendations. Generally, preventative maintenance should be performed at regular intervals, such as every 10,000 miles or every six months.

Q: What are some benefits of regular preventative maintenance for semi-trucks?

A: Regular preventative maintenance can help extend the life of the truck, improve fuel efficiency, reduce the risk of breakdowns and accidents, and maintain the value of the truck.

Q: How can technology be used to assist with preventative maintenance for semi-trucks?

A: Technology such as telematics systems and predictive analytics can help monitor the health of a semi-truck’s various systems and components, alerting drivers and maintenance teams when maintenance is needed. This can help prevent breakdowns and minimize downtime.

James Johnson is a former truck driver who now works as a writer, specializing in the trucking industry. With over 15 years of experience on the road, James has a unique perspective on the challenges and opportunities faced by truck drivers and the trucking industry as a whole. His writing focuses on issues such as safety, regulation, and the latest industry trends. His work has been featured in several trucking publications and he has received recognition for his contributions to the industry. In his free time, James still enjoys being around trucks and often attends truck shows and other industry events.